Expert Molding Technologies

Advanced engineering for high-quality molding.

- Asset Management

- Project Management

- Energy Efficiency

- Material Sourcing

Based in Trofarello, but with production capabilities all over the world, NMI is dedicated to finding and offering cutting-edge solutions to customers’ requests, that range from molding to assembly and automation.

Technology and precision

The core of our expertise

Advanced injection molding solutions

National Molding Italia is specialized in injection molding, co-injection molding, and overmolding. This includes overmolding between plastic materials (typically plastic-rubber) or overmolding of metal components, utilizing advanced 2K technology (bi-injection molding).

The company’s advanced machinery, automated feeding systems, and measuring technologies have enhanced production efficiency and service offerings, ensuring maximum quality from design feasibility to product realization.

Quality control system

National Molding Italia guarantees superior quality by utilizing a specially developed statistical process control system that monitors the production cycle in real-time.

Quality begins at the design stage, continues through the first prototypes, and extends to full production, with continuous monitoring across all production shifts and processing cycles.

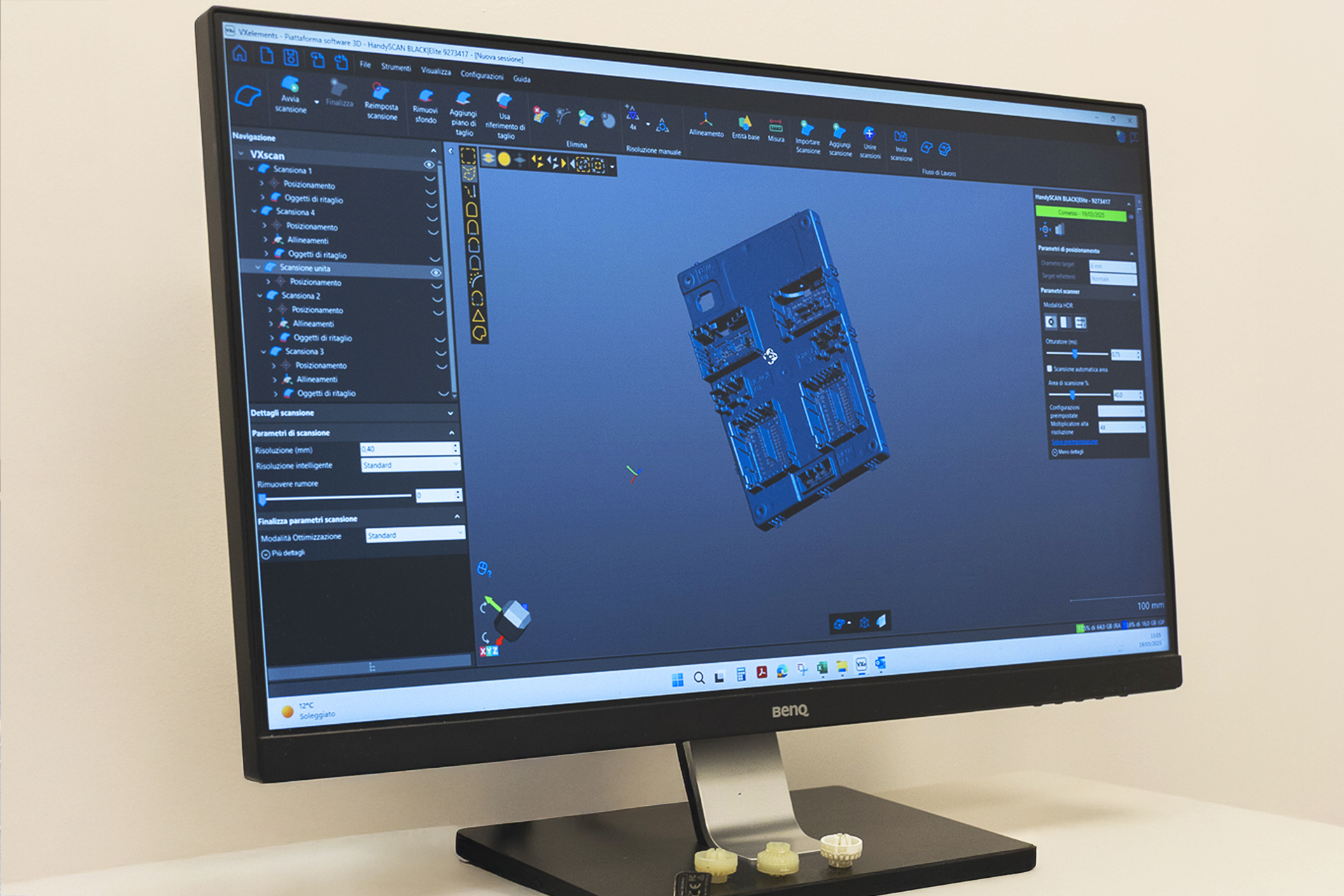

- Optical Machines

- Laser Scanners

- Profile Projectors

- DSC Machines

- Dynamometers

- Automatic 3D Coordinate Measuring Machines

- Climatic Chambers

Molding the future with recycled materials

We are all very aware that working with recycled materials can offer immense benefits.

At National Molding Italia, we embrace this approach by delivering advanced plastic molding solutions with recycled materials, contributing to a sustainable future with every project we undertake.

- Reducing raw material demand

- Conserving natural resources

- Protecting ecosystems

- Saving energy

- Cutting carbon emissions

Materials and performance

Engineering strength and versatility

Acetal polymers

Acetal, referred to as polyacetal and polyoxymethylene (POM) is a semi-crystalline, low friction engineering thermoplastic, offering exceptional strength, stiffness, and stability. This versatile material is characterized by:

- Wear resistance and longevity

- Impact resistance

- High elasticity and stress resistance

- Heat resistance

- Cehemical resistance.

Nylon polymers

Nylon is a family of versatile synthetic polymers, known as polyamides, characterized by high strength, durability, and low friction. At National Molding, nylon is available in three types:

- Nylon 6 – High strength, good chemical resistance, commonly used in applications that require durability and toughness.

- Nylon 66 – High melting point, good dimensional stability, and excellent wear resistance.

- Nylon 12 – Flexible and impact-resistant, good chemical resistance, and low moisture absorption.

Additional Polymers

Polycarbonate

Polycarbonate (PC), a technical amorphous thermoplastic material:

- transparent

- hygroscopic (absorbing moisture)

- with an excellent impact resistance

- with a good dimensional stability

- with a high temperature resistance

- ideal for products requiring durability and toughness.

Polybutylene therephtalate

Polybutylene therephtalate (PBT), a semy-cristalline thermoplastic engineering polymer:

- strong and rigid

- resistant to chemical agents (oils, greases, and solvents)

- with a low moisture absorption

- ideal for components subject to stress.

Polypropylene

Polypropylene (PP), a thermoplastic polymer slightly harder than polyethylene:

- lightweight with a lower density than water

- with an excellent resistance to a variety of chemical agents

- used at high temperatures (up to approximately 100 °C-120 °C) without losing its mechanical properties.

- fully recyclable

- ensuring durability in applications requiring mechanical strength.

Unity and interaction

The keys to success

The plant

› Strategic location

› 4,200 m² area of production and assembly

› Solar panels

› 1,800 m² warehouse

› 800 m² offices

The line

› 85 employees

› 30 presses from 25 tons to 550 tons

› 7 cranes

› Automated feeding system

› Injection, bi-injection, co-injection Molding

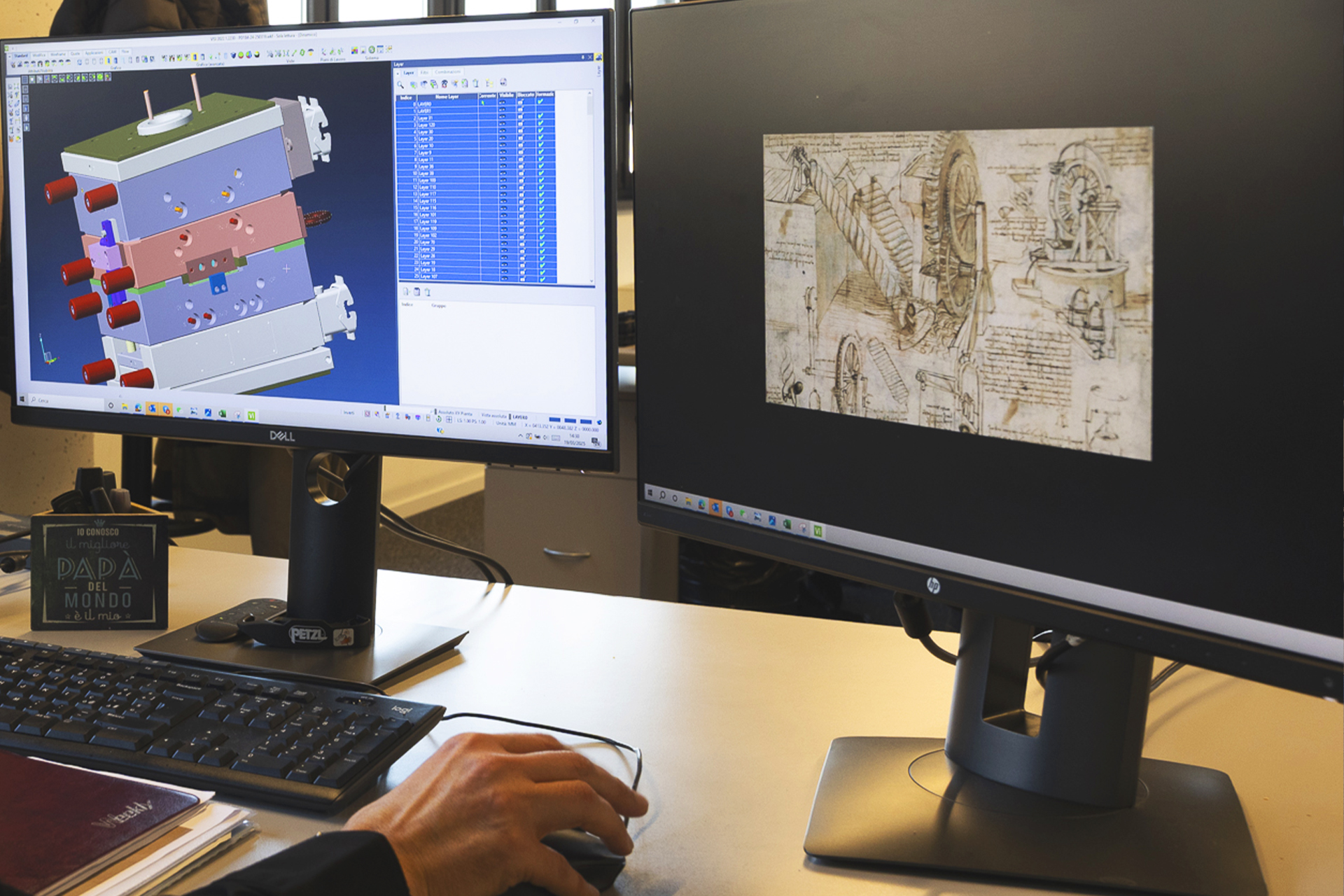

Organization

› Internal Technical Department

› Quality Department

› Metrology Laboratory

› Efficient workflow